Fertiliser types

Manure or fertiliser can occure in different forms and types. Liquid, solid, derived from manure processing,...

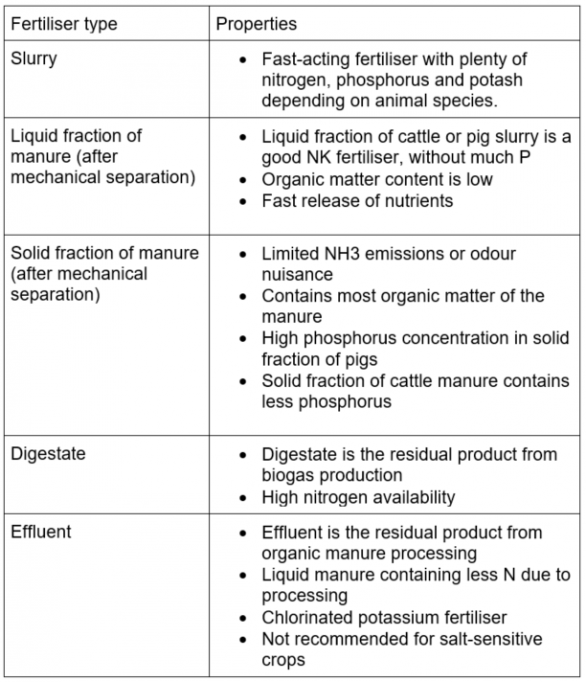

In the table* below a summary of the properties of different fertiliser types is made:

*From: H. Vanrespaille, S. Smets, M. Verbeke, A. Gorissen, L. Hex, A. Elsen, J. Bries (2018). Organische bemesting: Wat en hoe? Published by de Bodemkundige Dienst van België vzw, Heverlee

Digestate

In anaerobic digestion micro-organisms will largely decompose biomass (manure or organic waste) in the absence of oxygen. During the process, they produce biogas, which consists of methane (CH4) and CO2. This produces green energy. The semi liquid stream that remains after fermentation is called digestate.

Due to the differences in input materials, there is a large variation on composition. Most organic matter is digested during fermentation. Digestate will therefore contain nutrients that are easily released because they are not bound. Digestate is in general nitrogen rich. Digestate is best injected just before the growing season. This will allow maximum utilisation of the nutrients and there is less chance of leaching.

This information and more can be found in the practical guide organic fertilisers. (Vanrespaille, S. Smets, M. Verbeke, A. Gorissen, L. Hex, A. Elsen, J. Bries (2018). Organische bemesting: Wat en hoe? Published by de Bodemkundige Dienst van België vzw, Heverlee) (Dutch)

Effluent

Effluent is created when the nitrogen from the (liquid fraction of) slurry or digestate is converted to nitrate (nitrification) and then to nitrogen gas (denitrification) by aerobic and anaerobic bacteria, respectively. After treatment, the activated sludge is separated from the liquid fraction. This liquid fraction is called the effluent.

Effluent mainly consist of K, Mg, Na and Cl. It contains less nitrogen than slurry or digestate. With frequent use there is a risk of salinisation.

This information and more can be found in the practical guide organic fertilisers. (Vanrespaille, S. Smets, M. Verbeke, A. Gorissen, L. Hex, A. Elsen, J. Bries (2018). Organische bemesting: Wat en hoe? Published by de Bodemkundige Dienst van België vzw, Heverlee) (Dutch)

Washing water from chemical air washer

Chemical air washers are mostly used in pigsties, manure processing and composting plants. They function as an air treatment technique to reduce the ammonia emissions to the outdoor environment. The resulting washing water can be used as a nitrogen- and sulphur fertiliser. It is a relatively cheap, circular and local fertiliser.

In chemical air scrubbers, the barn air to be purified is drawn in. This air passes through a filter that is continuously humidified with a washing liquid acidified by sulphuric acid. The ammonia of the air reacts with the sulphuric acid to form ammonium sulphate. In a properly adjusted air scrubber, all the sulphuric acid present in the mist reacts with the ammonium from the air, and you get an aqueous solution with a (slightly) acidic pH (ammonium sulphate). For every kg of ammonia you want to remove from the barn air, you need about 1.5 litres of sulphuric acid.

More information in this infosheet and this text on washing water from chemical air washers (Dutch).

Here you can also find a mathematical example (Dutch) of using washing water from chemical air washers as a fertiliser.

Washing water from chemical air washers can be applied on grassland through a spoke wheel injector (see picture, spoke wheel injector in Belgium). More information on applying the washing water on grassland through a spoke wheel injector can be found in this infosheet (Dutch).